About Us

Who we are

One-Stop Zero-Carbon Energy Solution Provider

Q-SUN Group is a leading provider of integrated clean energy solutions, specializing in the research, development, production, and sales of photovoltaic modules. We are at the cutting edge of intelligent production and manufacturing within the photovoltaic industry. Founded in 2014, our international marketing center is situated in Nanjing, complemented by production facilities in Tian-chang, Yancheng. With over a decade of expertise in photovoltaic module R&D and production, Q-SUN Group delivers more than 4 GW of high-efficiency photovoltaic modules annually to nearly one million users across more than 50 countries and regions worldwide, continuously generating electricity and economic benefits for our global clientele.

Corporate vision: Since its establishment, Q-SUN Group has been adhering to mission of "Share sunshine value with the world", continuously providing excellent green energy and services to the society. Relying on the advantages of scale, innovation and talents formed for a long time, it devotes itself to leading photovoltaic technology and indus-try, and accelerating the early arrival of the "Grid-Parity Era" for solar power, so as to change the way human beings use energy, change the power mix of the world, and change humans beings' lifestyle.

Corporate vision: Since its establishment, Q-SUN Group has been adhering to mission of "Share sunshine value with the world", continuously providing excellent green energy and services to the society. Relying on the advantages of scale, innovation and talents formed for a long time, it devotes itself to leading photovoltaic technology and indus-try, and accelerating the early arrival of the "Grid-Parity Era" for solar power, so as to change the way human beings use energy, change the power mix of the world, and change humans beings' lifestyle.

Founded in 2014, our international marketing center is situated in Nanjing, complemented by production facilities in Tianchang and Yancheng.

Annual Capacity

0

GW

Production Base

0

Covered Countries

0

+

Annual Orders

0

+

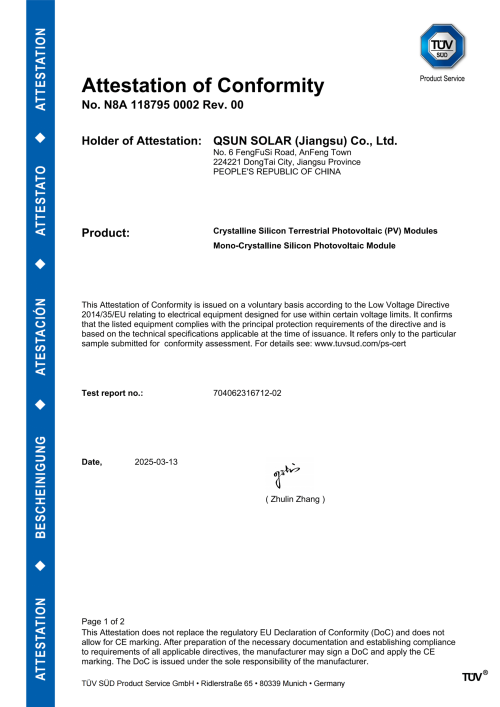

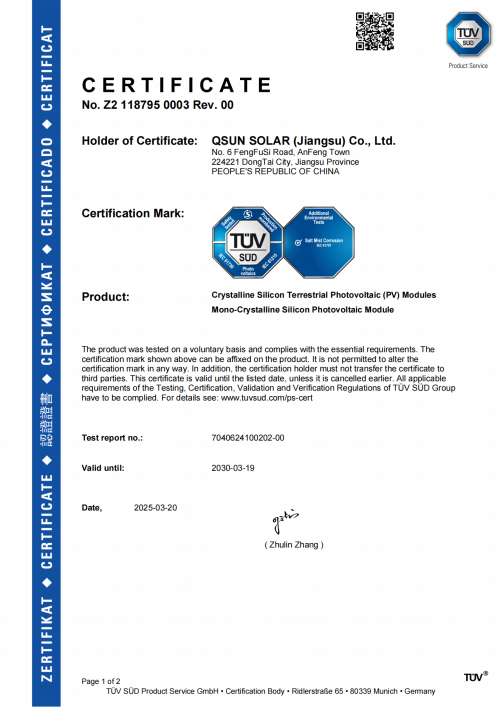

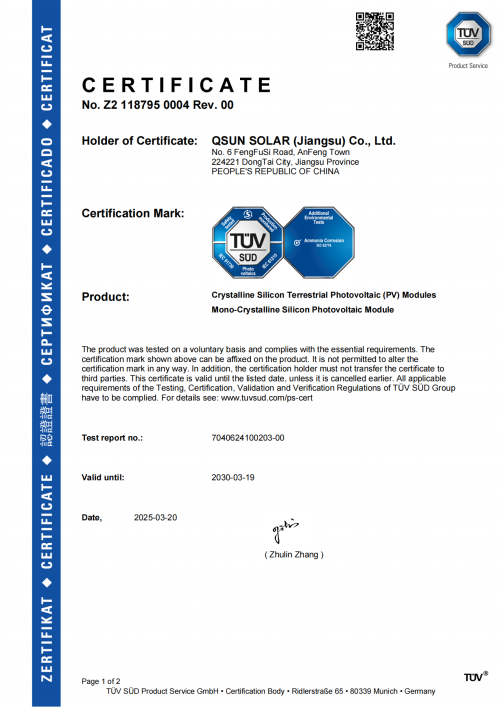

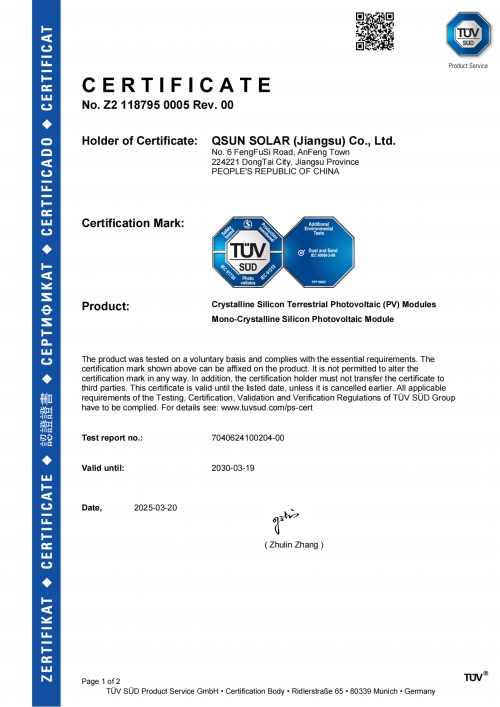

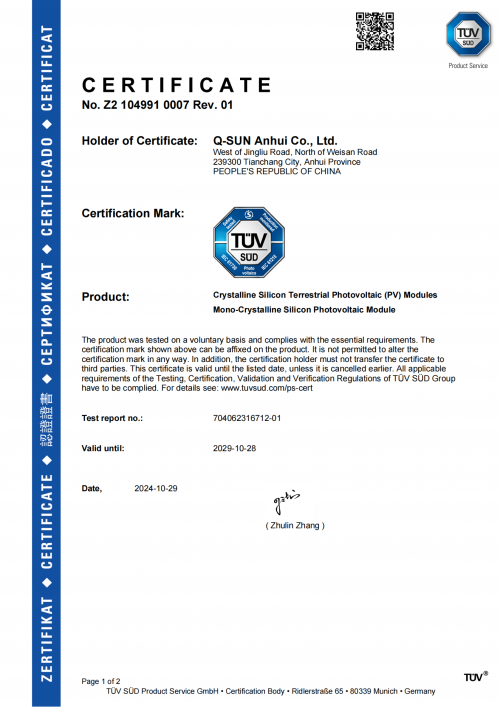

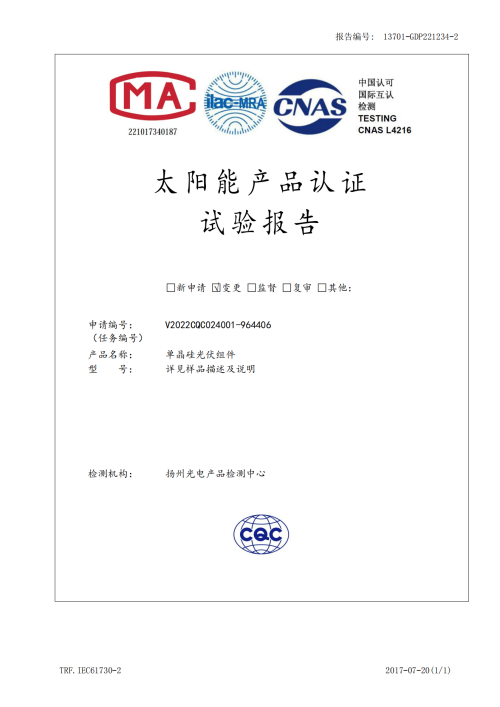

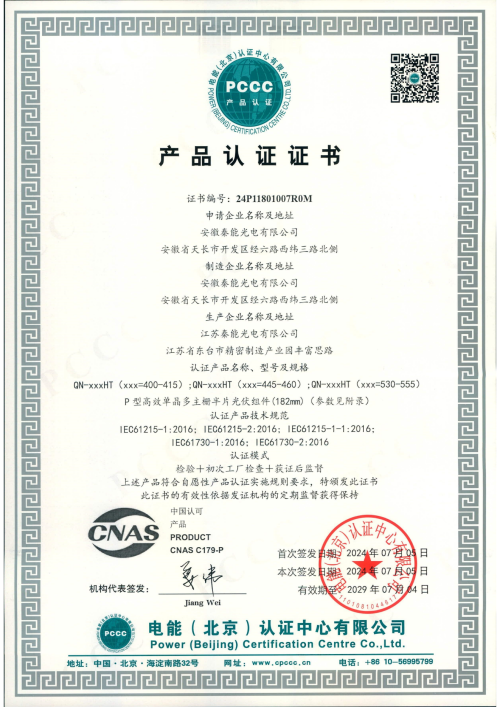

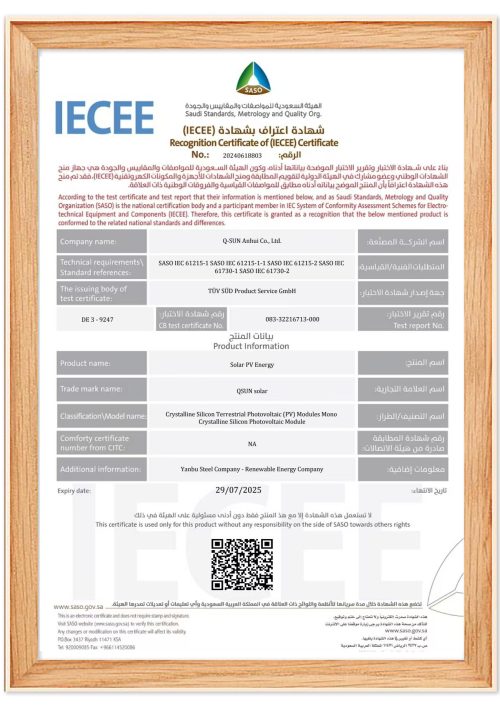

QUALIFICATION CERTIFICATE

![{"mCoordarray":[584,531,3210,511,3241,4331,458,4264],"mFilterType":0,"mOffset":6118306,"mCameraMatrix":[0,0,0,0,0,0,0,0,1],"mSession":"1732503522043"}](https://www.q-sunsolar.com/wp-content/uploads/elementor/thumbs/TianChang-Occupational-Health-and-Safety-Management-System-Certificate-scaled-r5q7ag670so6n2qfau18kjo9k240sr1qnsvi9ryy72.jpg)

![{"mCoordarray":[690,641,3149,623,3318,4238,562,4264],"mFilterType":0,"mOffset":6077559,"mCameraMatrix":[0,0,0,0,0,0,0,0,1],"mSession":"1732503233900"}](https://www.q-sunsolar.com/wp-content/uploads/elementor/thumbs/TianChang-Environmental-Management-System-Certification-scaled-r5q7a5tyxma13d5fz7kcb4a70tizg2woydp5zqea3i.jpg)

![{"mCoordarray":[832,593,3444,614,3319,4371,692,4187],"mFilterType":0,"mOffset":6021303,"mCameraMatrix":[0,0,0,0,0,0,0,0,1],"mSession":"1732503680450"}](https://www.q-sunsolar.com/wp-content/uploads/elementor/thumbs/TianChang-Quality-Management-System-Certificate-scaled-r5q7aqif3z2c6sbemgi4tz2c3ap25f6sd81ujtjmam.jpg)

![{"mCoordarray":[789,574,4477,576,4423,3346,662,3146],"mFilterType":0,"mOffset":5503940,"mCameraMatrix":[0,0,0,0,0,0,0,0,1],"mSession":"1737514564764","mOrientation":6}](https://www.q-sunsolar.com/wp-content/uploads/elementor/thumbs/Environmental-Management-System-Certification-scaled-2-scaled-r5g7nls6cbf1yqqwrzmmb4y8edgicvz2yvfnbydvvi.jpeg)

![{"mCoordarray":[719,736,4665,820,4660,3561,665,3619],"mFilterType":0,"mOffset":4712528,"mCameraMatrix":[0,0,0,0,0,0,0,0,1],"mSession":"1737514564764","mOrientation":8}](https://www.q-sunsolar.com/wp-content/uploads/elementor/thumbs/Occupational-Health-and-Safety-Management-System-Certificate-scaled-1-scaled-r5g7ny02t5vs5o95smwrpjv84dsa4yblcjwykjvrmm.jpeg)

![{"mCoordarray":[888,491,5002,574,4871,3488,815,3388],"mFilterType":0,"mOffset":5378632,"mCameraMatrix":[0,0,0,0,0,0,0,0,1],"mSession":"1737514564764","mOrientation":8}](https://www.q-sunsolar.com/wp-content/uploads/elementor/thumbs/Quality-Management-System-Certificate-scaled-1-scaled-r5g7o9a536b80zsryrsajh0r908opbkde3qsbvf1jy.jpeg)

Smarter Manufacturing More Guaranteed Quality

Q-SUN Solar has steadfastly worked with its partners to overcome any technical issues encountered for the plant layout, a completed set of highly automated manufacturing architecture has been developed. ln addition, Q-SUN Solar also uses statistical engineering, equipment control,and a variety of management systems to achieve lean production. While ensuring the consistency of product quality, we also strive to shorten the yield learning curve and new product mass production cycle, reduce production costs, and improve customer’s profitability.

HIGHLY AUTOMATED

REDUCE PRODUCTION COSTS

IMPROVE CUSTOMER PROFITABILITY

High-efficiency And High-flexibility Modular Automatic Production Line

To achieve a high utilization rate and efficiency, Q-SUN Solar has divided the entire production chain into separate but closely united automated production sectors. Over 40 patents are applied on the production process optimization, which effectively avoids manual errors and makes sure all the production processes from raw material inspection to packing are all monitored online and saved for later use.

At the same time, the production department collects data from various key monitoring points in the production process to achieve further improvement in equipment manufacturing process and yield.

At the same time, the production department collects data from various key monitoring points in the production process to achieve further improvement in equipment manufacturing process and yield.

16%

Lower production cost

16%

Higher equipment effectiveness

24*7

Real-time online monitoring

100+

Production process optimization

99.9%

Good product yield rate

36%

Higher production efficiency

Quality Management System

Q-SUN Solar has received certifications for Quality Management System (ISO 9001: 2015), Environment Management System (ISO 14001: 2015) and Occupational Health and Safety Management System (ISO45001: 2018) from both DNV and GZCC.Beyond IS09001, Q-SUN Solar also applied for the national "GB T19580 2012 Criteria for Performance Excellence". This regulates not only product quality, but also production waste, environmental burden, management foresight etc., which are the necessary requirements for an "excellent" company.

Real-Time Monitored And Recorded

From incoming material testing to online production, OBA test and delivery status, Q-SUN Solar in-house developed MES system inter connects all data in one database to achieve completetraceability. The system implements a unique bar code for each module component. lnformation such as raw material suppliers, production workers, quality testing results, and production details are all accessible online through our MES system. This data is kept on our server for client's access, and allows us to track and take responsibility for product full cycle monitoring and production process optimization.

Standards IEC61215 And IEC61730

IEC Standards includes a series of tests for thermal cycling, damp heat, PID, UV, humidity freeze and hot spot. lt is designed to test whether or not modules can maintain their power output during adverse conditions throughout their lifetime.